The SemaCyte® Kit

SemaCyte® microcarriers are used to barcode, move, and freeze adherent cells for more powerful cell assaying workflows. Seeding Dishes contain arrays of barcoded microcarriers immobilised onto the bottom of standard tissue culture plasticware. Cells can be seeded onto the array as per standard tissue culture protocols. Once cells have attached, SemaCytes can be released into suspension and collected in cryovials for storage, mixed for multiplexing, and dispensed into microplates for assaying with your prefered reagents and equipment.

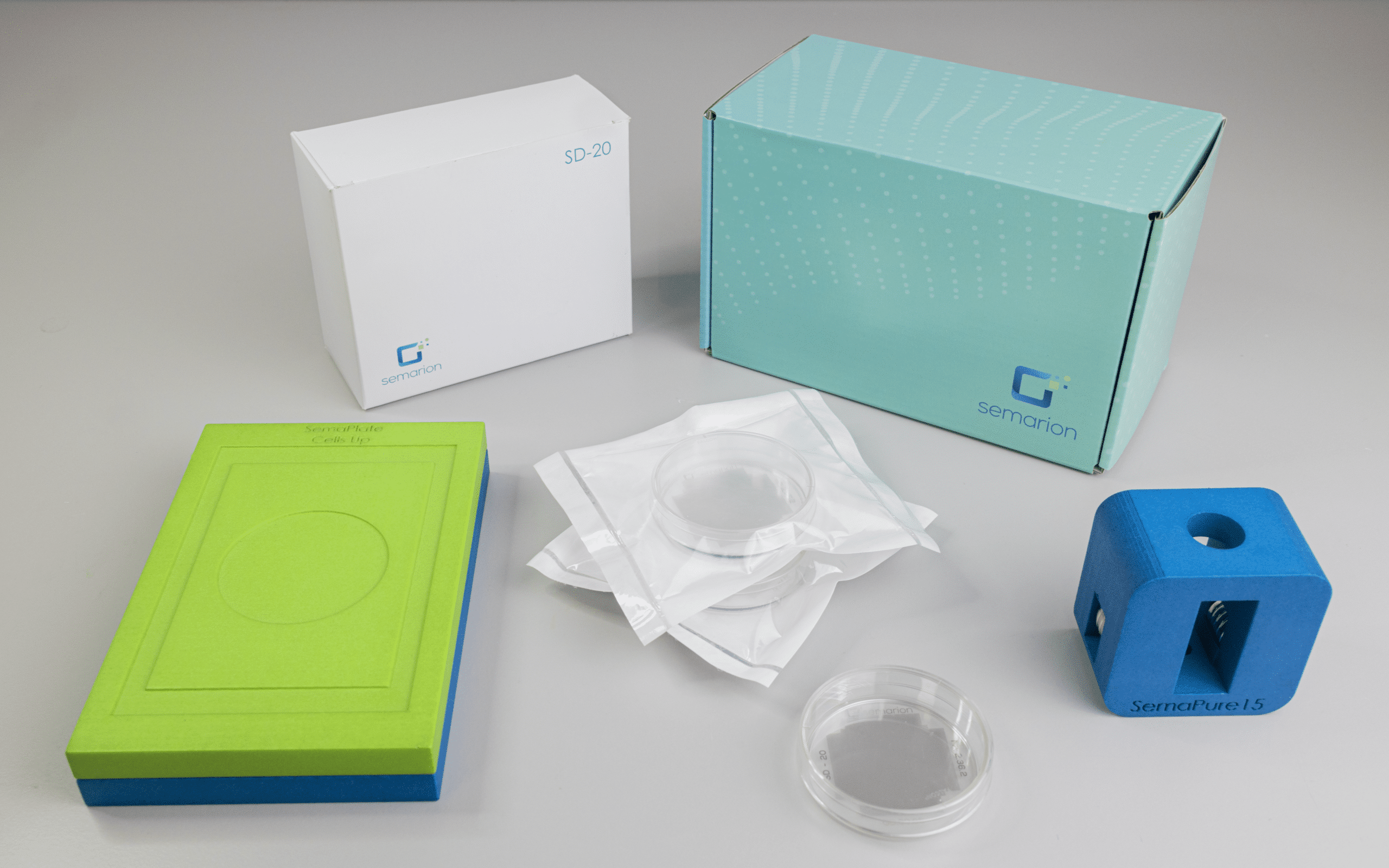

SemaCyte Starter Kit contents: Seeding Dish 20, SD20 (3x), SemaPure15 (1x), SemaPlate (1x)

Benefits of SemaCyte® Microcarriers

Multiplex cells in a single well to accelerate panel screens

Use adherent assay-ready cells within 1 hour from thawing

Dispense less cells-per-well but retain high local confluency

Seeding Dishes

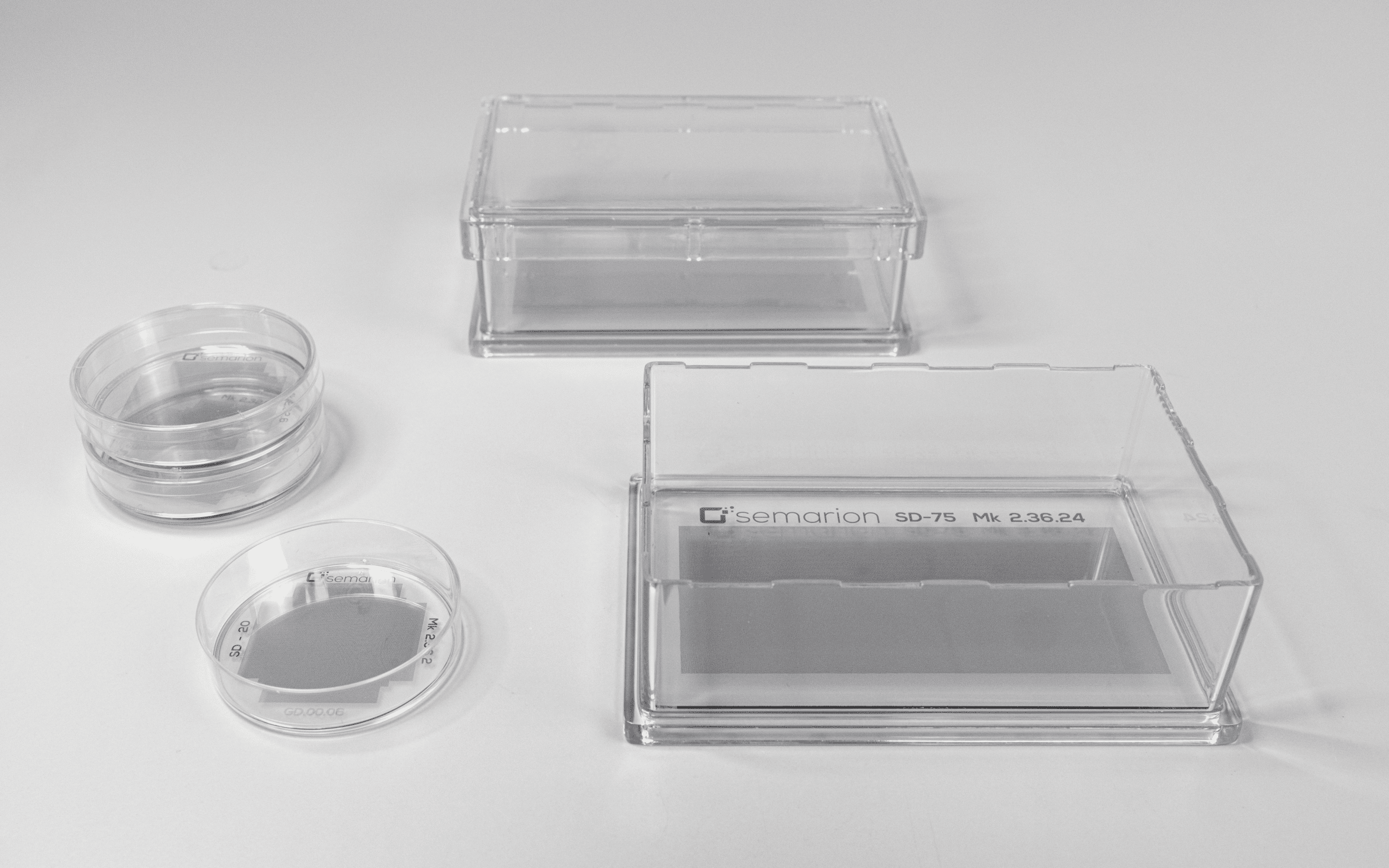

A 20 cm² Seeding Dish (SD20) contains 50,000 immobilised SemaCytes with a single optical barcode, enabling straightforward cell capture using standard culture practice.

Each SemaCyte provides a 100 × 100 µm² growth area to capture 1–30 cells per microcarrier, depending on cell type and seeding conditions. Surfaces can be coated with cell attachment polymers.

Each SD20 produces enough SemaCytes for 2–10 microplates. Recommended densities are 10–200 SemaCytes per well in 384-well plates, depending on the assay.

Various dish formats (SD20, SD75, SD225) and barcode sets are available on request.

Peripherals

SemaCytes are designed to plug into standard microplate workflows and are compatible with common assay types and readouts, including imaging and plate-reader assays.

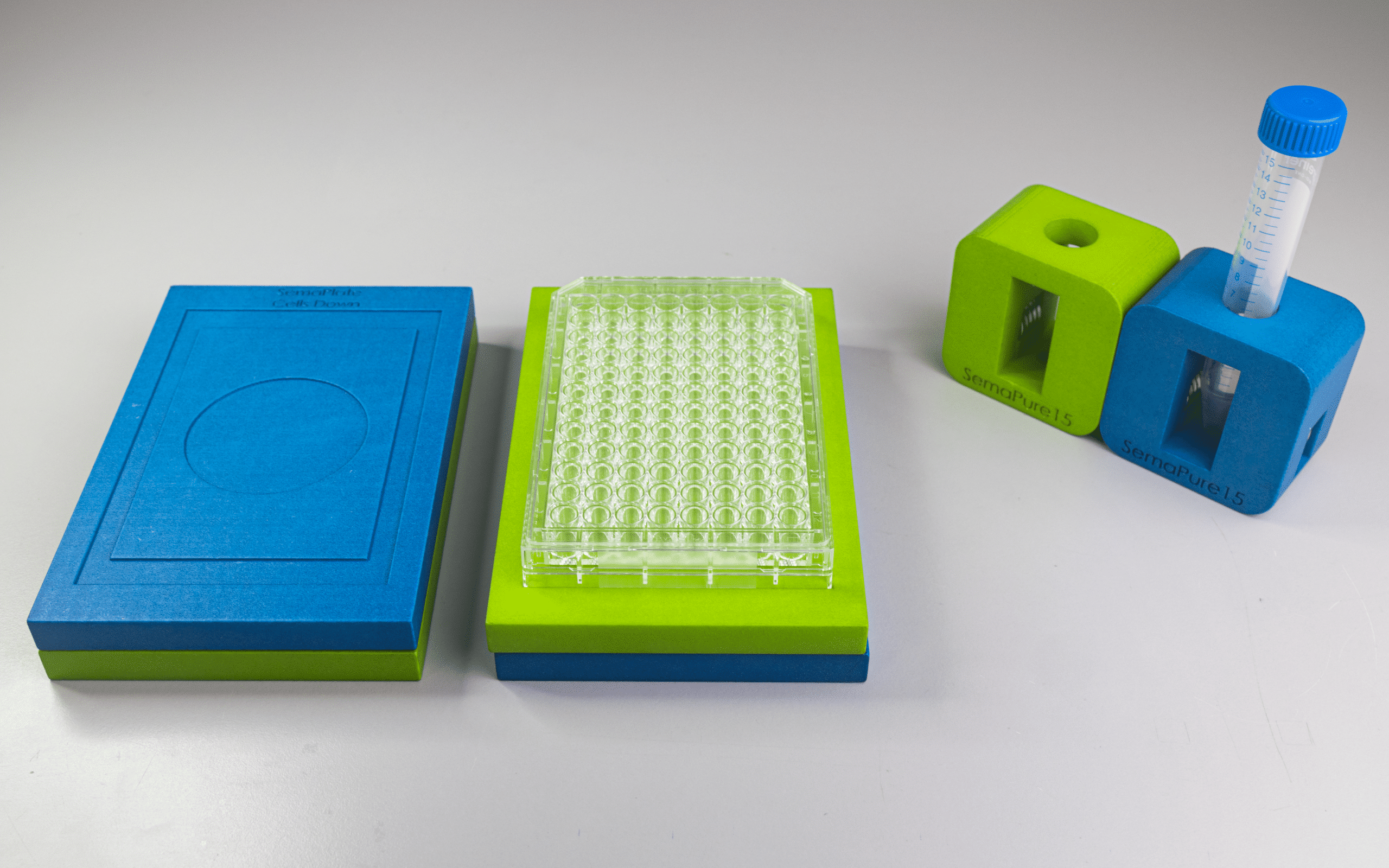

SemaPure15 purifies SemaCytes after cell attachment and release.

SemaPlate orients and immobilises SemaCytes inside microplates. In typical workflows it is used during dispensing to pull SemaCytes to the bottom of the well and achieve consistent positioning, after which downstream assay steps can be performed without the magnet.

Semalyse

SemaCytes carry QR-code-like optical barcodes in the rim that are visible in the brightfield channel. After imaging, software detects and isolates individual microcarriers, then decodes each barcode by matching it to a reference and generates barcode-separated image sets for each cell type.

Barcode deconvolution can be performed using Semalyse or microscopy providers’ built-in tools such as Harmony. For downstream analysis, deconvoluted images can be processed in standard pipelines, including ImageJ and CellProfiler.

Pricing & Cost Impact

Unit pricing: The unit price depends on Seeding Dish format (SD20, SD75, SD225), barcode requirements, and order volume. If you share your assay format and multiplexing plan, we can quote and recommend a suitable microcarrier density.

How to think about cost: SemaCytes add a consumable line item, but they are typically adopted when the overall screening campaign becomes cheaper and faster through multiplexing, assay-ready cells, and miniaturisation.

Budgeting guidance: Many imaging workflows start at ~20 SemaCytes per cell type per well (assay dependent). As a planning range, this often maps to £0.10–£0.50 per cell type per well. In a 4-plex design that becomes ~£0.40–£2.00 per well, or ~£160–£800 per 384-well plate, depending on the final density, dish format, and order volume.

Multiplexing capacity: Typical validated workflows support 8 and 32 cell models per well for 384 and 96-well plates, respectively.

Software: Semalyse is provided free, and barcode deconvolution is also supported in Harmony and Signals Image Artist workflows.

Where Cost Savings Come From

Multiplexing reduces plate count: run multiple cell models in the same well, so campaigns can use fewer plates, less reagent, and less imaging time.

Assay-ready adherent cells reduce labour: batch prepare and cryopreserve adhered cells to remove the repeated seeding and attachment step and increase scheduling flexibility.

Miniaturisation boosts expensive-cell ROI: use fewer cells per condition, which is especially valuable for iPSC-derived or patient-derived models.